Socket Set Screws Manufacturing

Professional manufacturer with 10 production lines specializing in precision socket set screws for global industry leaders.

Serving Fortune 500 Companies • Siemens & Philips Approved Supplier • Custom Production Available

Trusted by Industry Leaders:

Socket Set Screws Applications

Discover how our precision-engineered socket set screws deliver reliable fastening solutions across diverse industries and demanding applications.

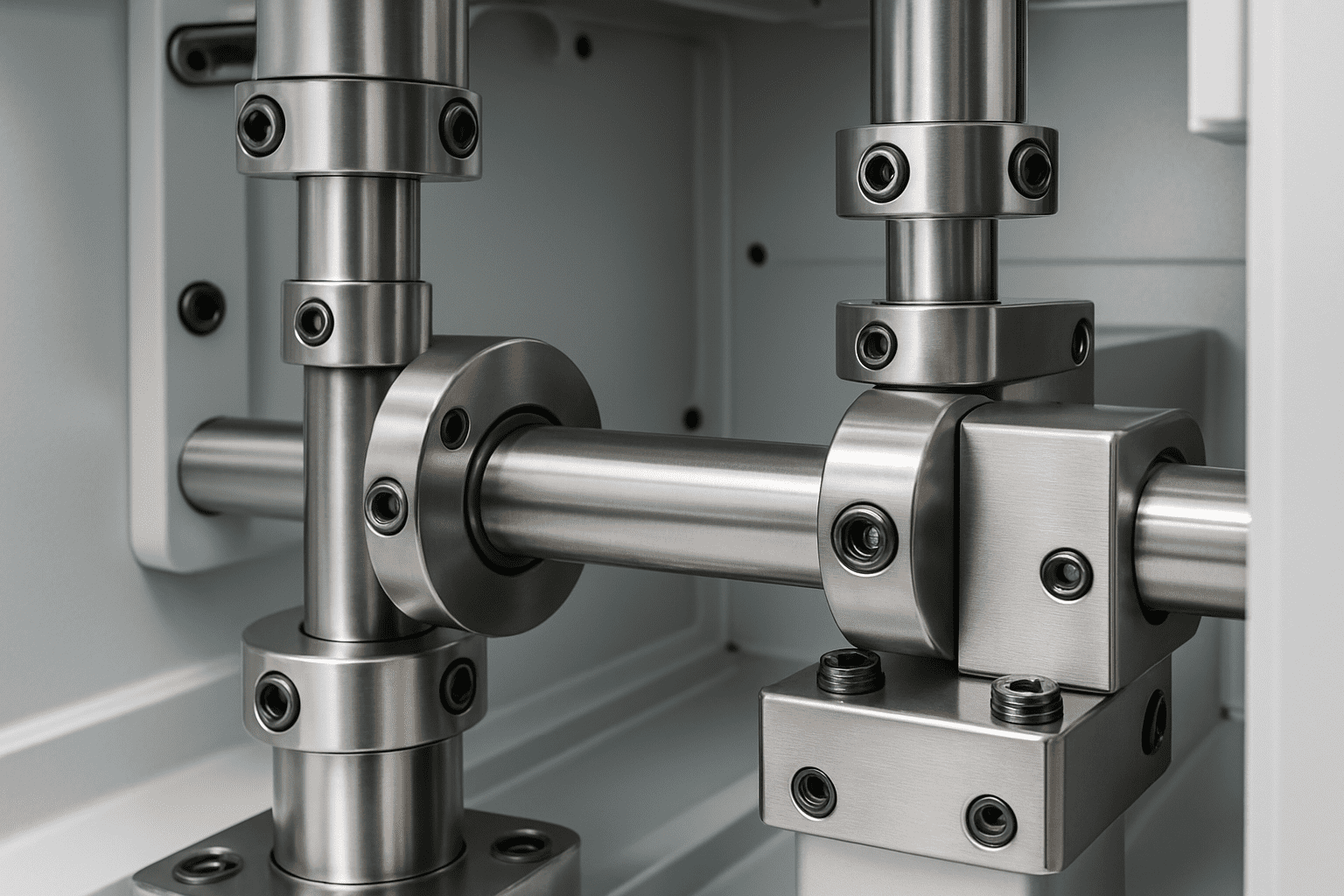

Mechanical Equipment

Essential for securing shafts, collars, and positioning components in precision machinery, pumps, and industrial equipment requiring reliable torque transmission.

- Shaft Collars & Hubs

- Bearing Assemblies

- Positioning Systems

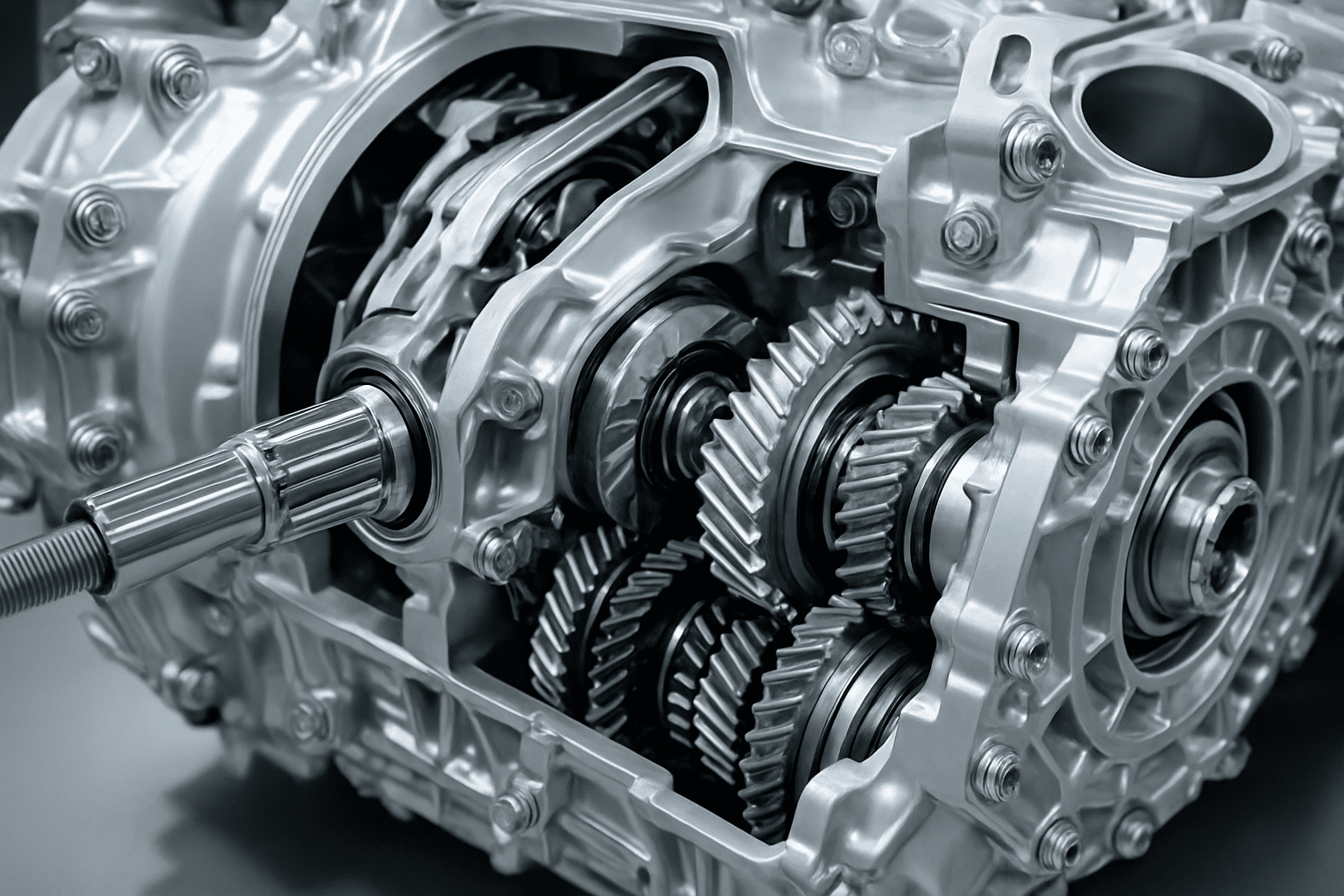

Automotive Industry

Critical fasteners for engine components, transmission assemblies, and chassis systems where vibration resistance and precise positioning are paramount.

- Engine & Transmission

- Suspension Components

- Brake System Parts

Electronics Assembly

Miniature socket set screws for precise positioning in electronic enclosures, circuit boards, and delicate assembly applications requiring exact alignment.

- PCB Mounting Systems

- Connector Assemblies

- Heat Sink Attachments

Construction Hardware

Heavy-duty fastening solutions for structural connections, architectural hardware, and building systems requiring permanent positioning and high load capacity.

- Structural Connections

- Door & Window Hardware

- Railing Systems

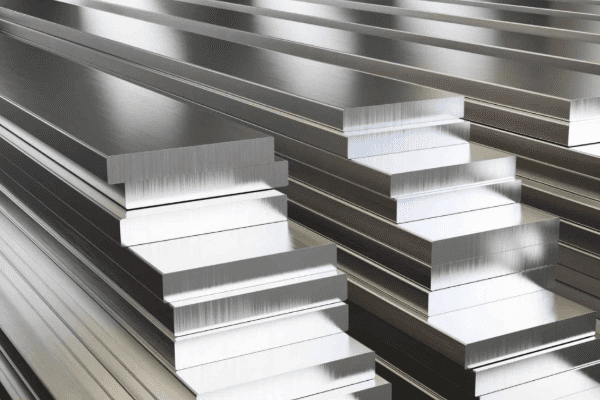

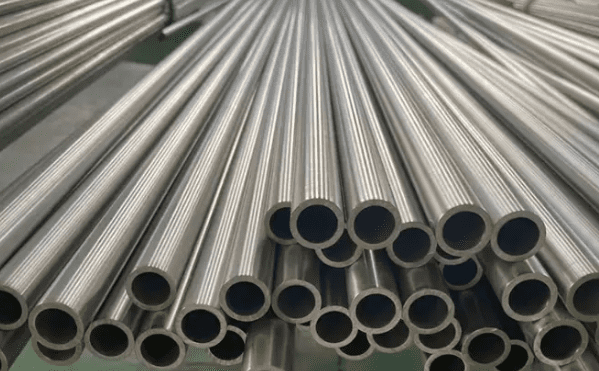

Premium Materials Selection

Our Socket Set Screws are manufactured using premium-grade aluminum and stainless steel, with advanced surface treatments to meet the most demanding industrial applications.

Aluminum Alloys

Lightweight • Corrosion Resistant • Superior Machinability

Stainless Steel

High Strength • Anti-Rust • Superior Corrosion Resistance

Material Comparison Chart

Choose the perfect material for your application based on performance characteristics

| Material Grade | Hardness | Corrosion Resistance | Weight | Primary Applications | Surface Treatment |

|---|---|---|---|---|---|

|

Al 6061-T6

Aluminum Alloy

|

HB 80-100 |

|

Light | Electronic Equipment General Industrial |

Anodizing Hard Anodizing |

|

Al 7075-T6

Aluminum Alloy

|

HB 80-100 |

|

Light | Aerospace Components High-Load Applications |

Anodizing Bead Blasting |

|

304 Stainless

A2-70 Standard

|

HRC 22-45 |

|

Medium | General Mechanical Equipment Applications |

Passivation Polishing |

|

316 Stainless

A4-80 Marine Grade

|

HRC 22-45 |

|

Medium | Marine Environment High-Humidity Applications |

Black Oxide Bead Blasting |

Aluminum Alloys

Lightweight • Corrosion Resistant • Superior Machinability

Al 6061-T6

Optimal balance of strength and machinability, the most commonly used industrial-grade aluminum material.

Al 7075-T6

High-strength aluminum alloy approaching steel strength, ideal for high-load environments.

Key Features:

- Lightweight design

- Excellent corrosion resistance

- Superior thermal conductivity

- Precise thread machining capability

Stainless Steel

High Strength • Anti-Rust • Superior Corrosion Resistance

304 (A2-70)

Most commonly used stainless steel, combining strength with rust resistance, suitable for most mechanical and equipment applications.

316 (A4-80)

Contains molybdenum for enhanced corrosion resistance, especially suitable for marine or high-humidity environments.

Key Features:

- High strength and durability

- Rust and corrosion proof

- Long-term outdoor/humid environment use

- High thread precision and stable torque

Advanced Surface Treatments

Enhance performance and longevity with our comprehensive range of surface treatment options.

Aluminum Surface Treatments

Anodizing

Silver, Black, NaturalEnhances corrosion resistance and surface hardness while improving aesthetic appeal.

Hard Anodizing

Dark Gray to BlackFurther increases surface hardness and wear resistance with matte finish.

Bead Blasting + Anodizing

Industrial Silver GrayProvides fine, uniform matte metallic texture with industrial-grade appearance.

Stainless Steel Surface Treatments

Passivation

Silver White NaturalRemoves surface free iron and enhances oxidation resistance capability.

Polishing

Bright Mirror/Fine MatteImproves surface smoothness and reduces friction coefficient for enhanced performance.

Bead Blasting

Uniform Silver GrayCreates uniform, fine industrial matte surface with consistent texture.

Standards & Precision

Drive Type

Hex Socket (Internal Hexagon)

Thread Precision

ISO 6g / ANSI 3A Standards

Hardness Range

Prime Quality Assurance

Every Socket Set Screw from Prime meets international standards and custom requirements, from material selection to surface treatment - ensuring reliable performance in your applications.

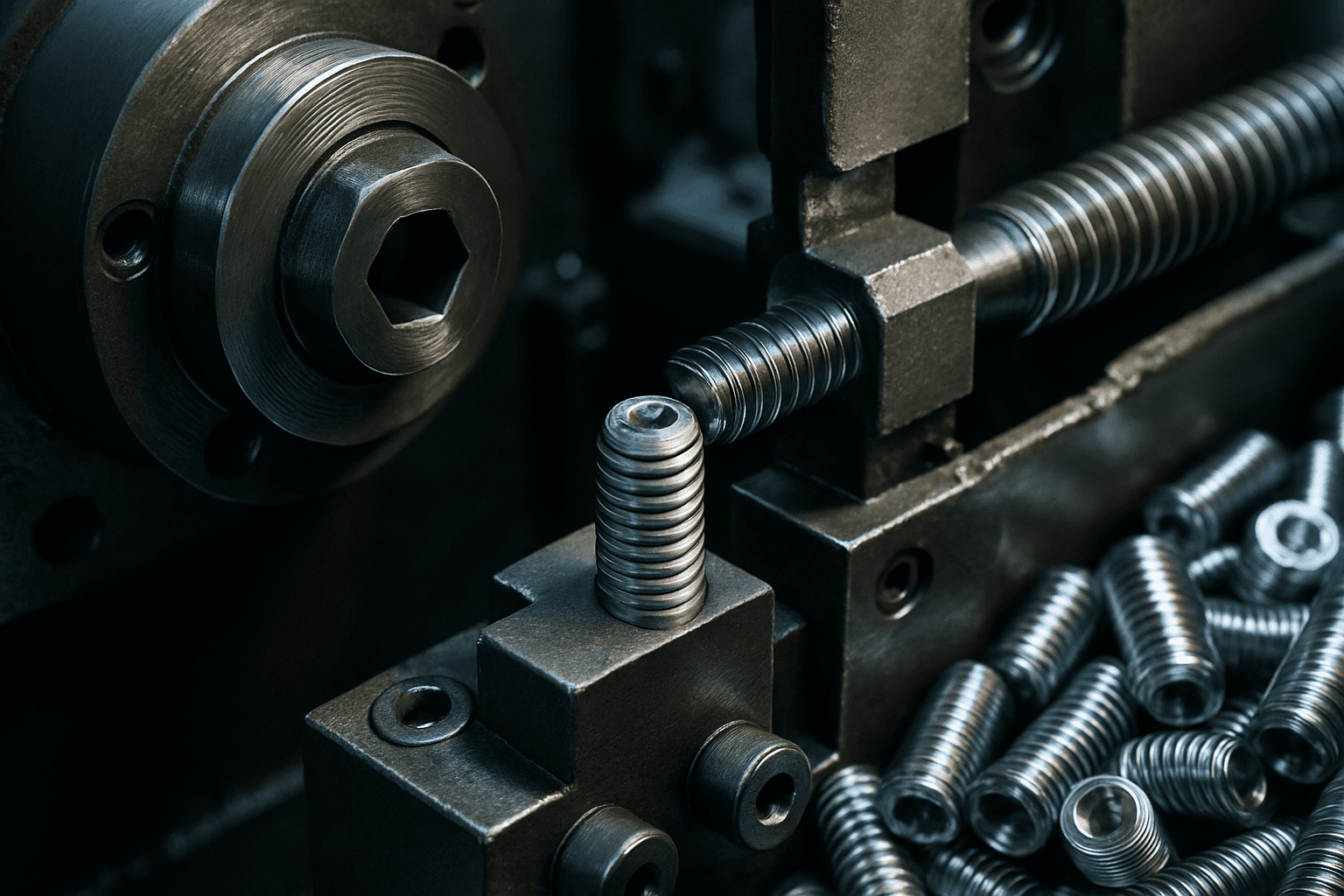

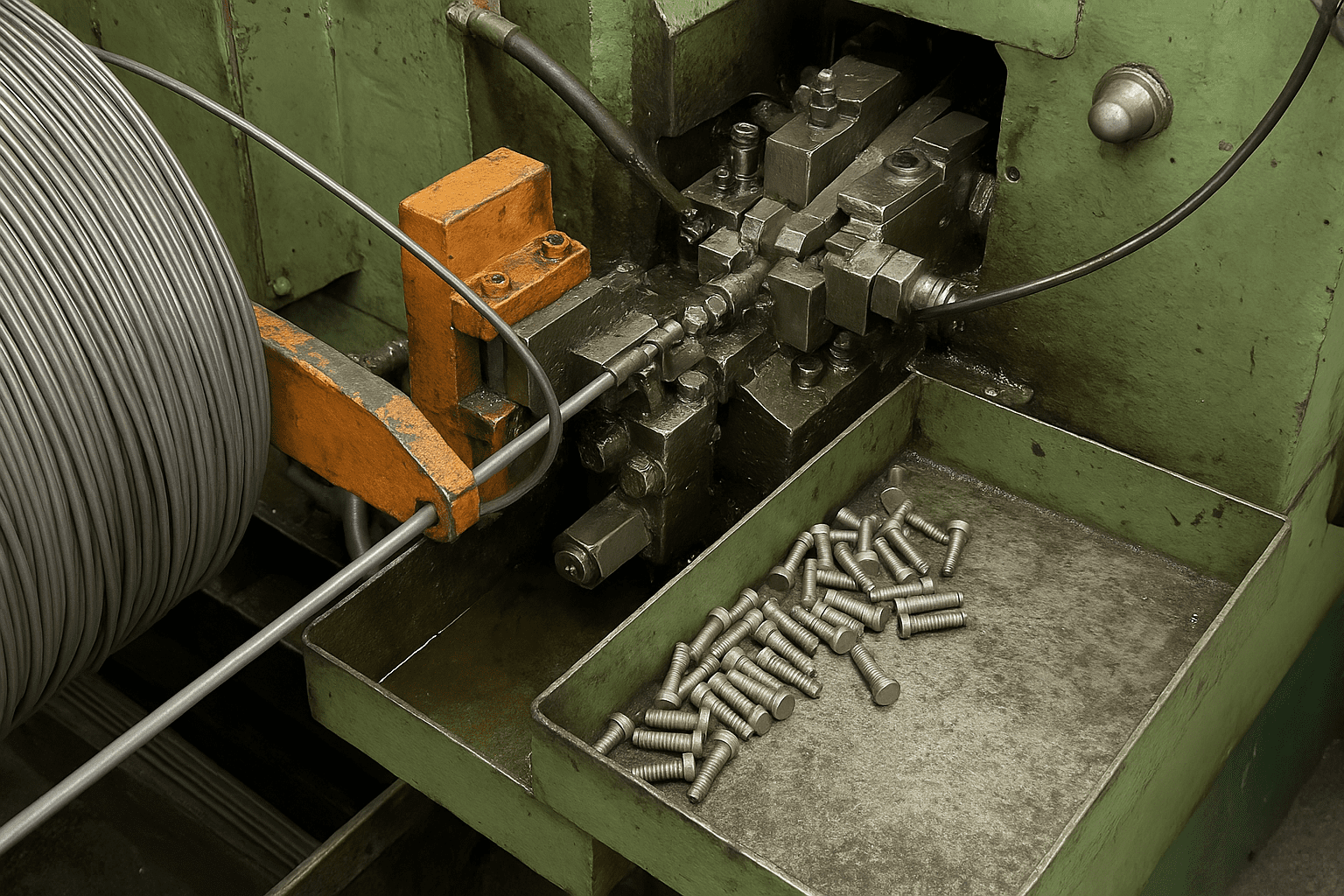

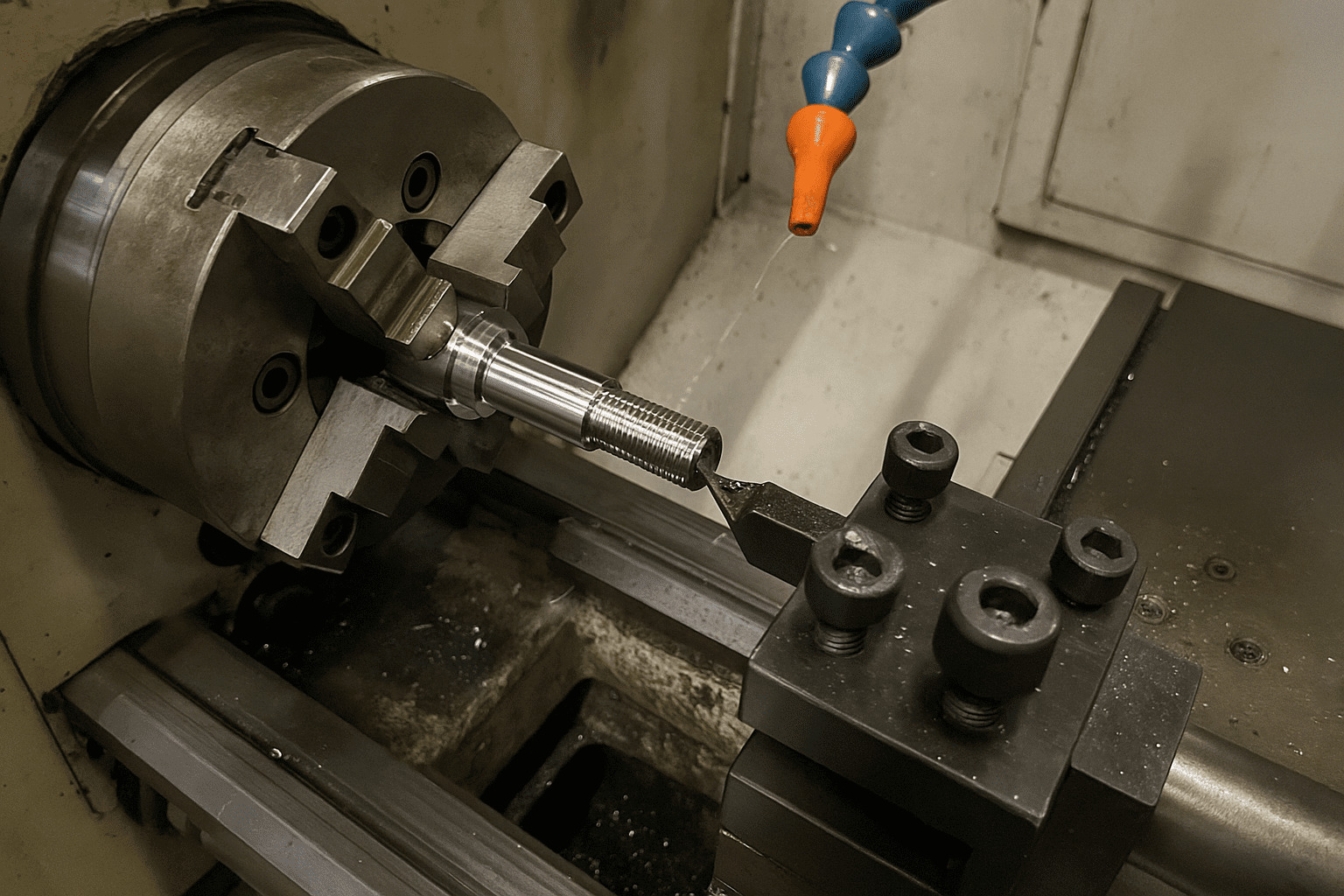

Precision Manufacturing Process

Precision manufacturing where every detail determines connection reliability. From raw materials to finished products, we strictly control every process to ensure each Socket Set Screw meets international quality standards.

Cold Heading

Using automated multi-station cold heading machines, high-quality metal wire is pressed into screw blanks at room temperature. This process ensures continuous metal fibers and dense structure, enhancing strength and toughness.

- Material utilization up to 95%

- Shape consistency ±0.02mm

- High batch production efficiency

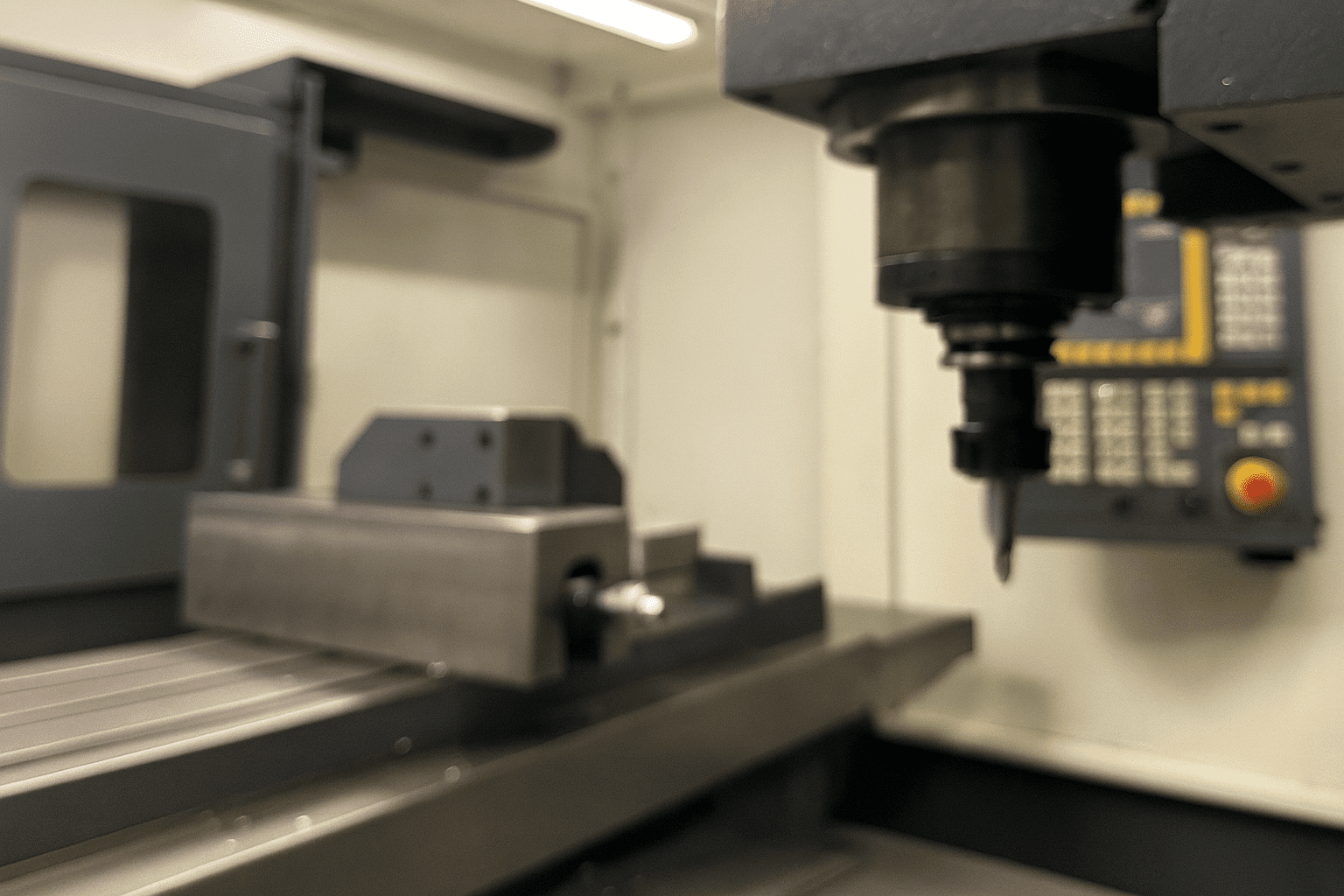

CNC Turning

Using high-precision CNC lathes for precise machining of threads, end faces, and hex socket holes. Ensuring thread accuracy, hex depth, and end face perpendicularity of each screw meets international standards.

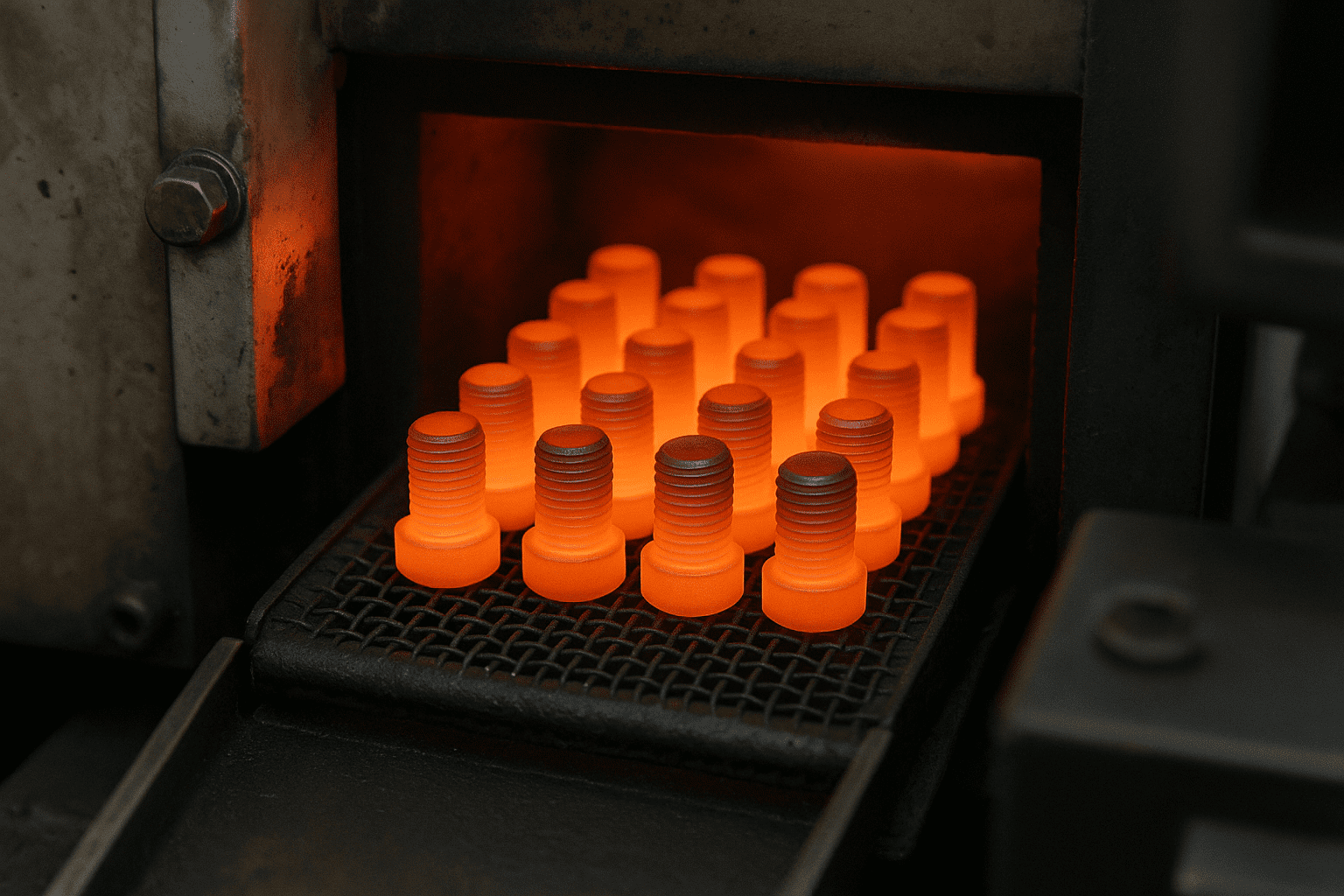

Heat Treatment

Quenching and tempering treatment for stainless steel and alloy steel set screws, optimizing hardness and toughness to maintain stable performance under high torque assembly conditions.

Surface Treatment

Multiple surface protection processes including passivation, polishing, blackening, and anodizing to enhance corrosion resistance and appearance quality.

Quality Inspection

Multiple quality control measures including thread ring gauges, torque testing, hardness detection, and complete visual inspection to ensure product consistency.

Packaging & Shipping

Moisture-proof and shock-resistant packaging with VCI anti-rust bags and ISPM-15 plywood boxes, supporting custom labeling requirements.

Ready for Your Custom Socket Set Screws?

Experience the Prime difference with precision manufacturing and global quality standards.

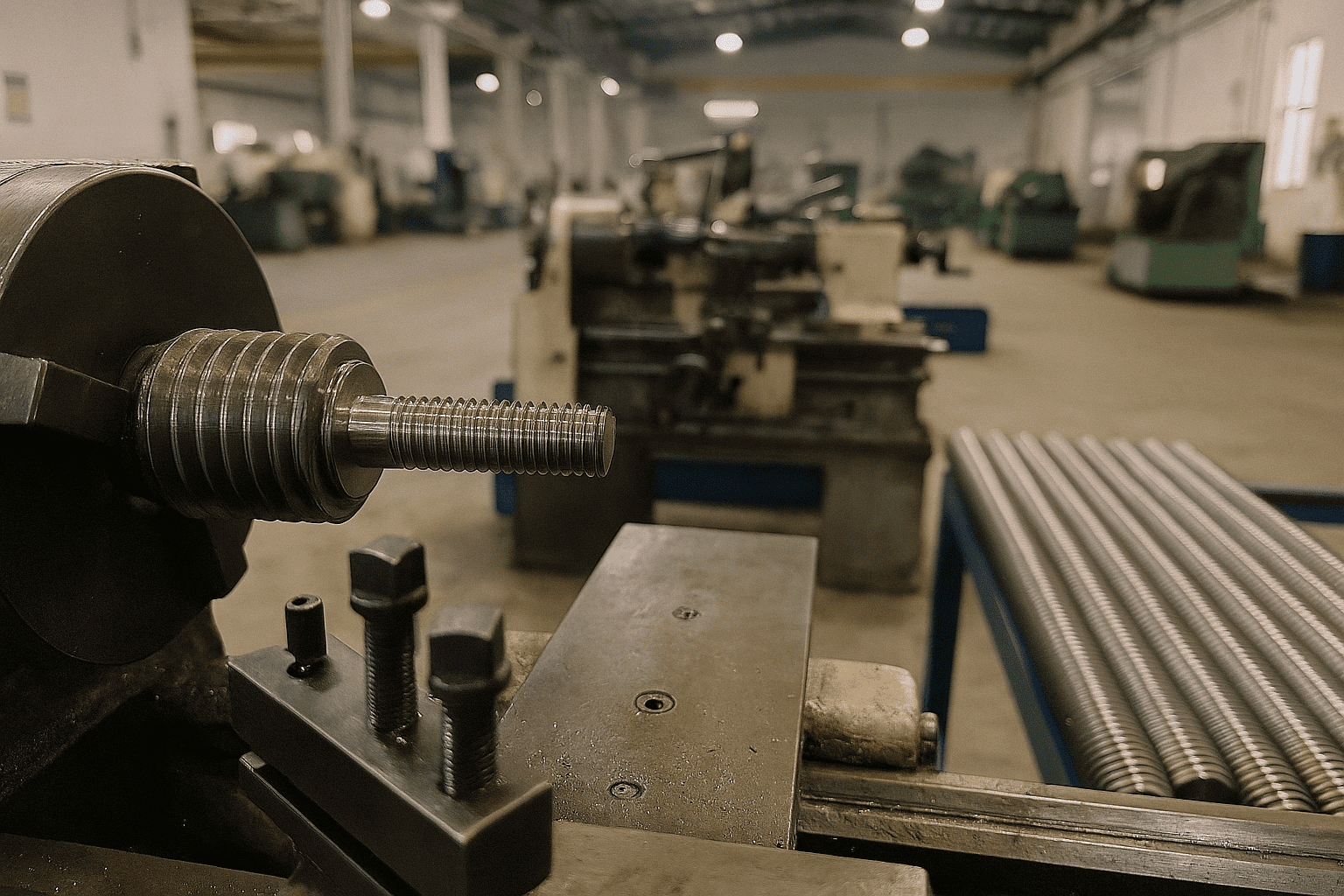

State-of-the-Art Manufacturing Facility

Our advanced production facility features 10 dedicated lines for Socket Set Screw manufacturing, equipped with precision machinery and comprehensive quality control systems.

Advanced Production Lines

10 automated production lines manufacturing precision Socket Set Screws

CNC Precision Equipment

High-precision machining

Threading Workshop

Precision thread cutting and finishing

Heat Treatment

Strength and durability enhancement

Automated Packaging

Secure export-ready packaging

Manufacturing Excellence Since 1993

Our facility combines decades of expertise with cutting-edge technology to deliver Socket Set Screws that meet the highest international standards.

Just a Few of the Partners Who Trust Our Quality

*Logos are property of their respective owners.

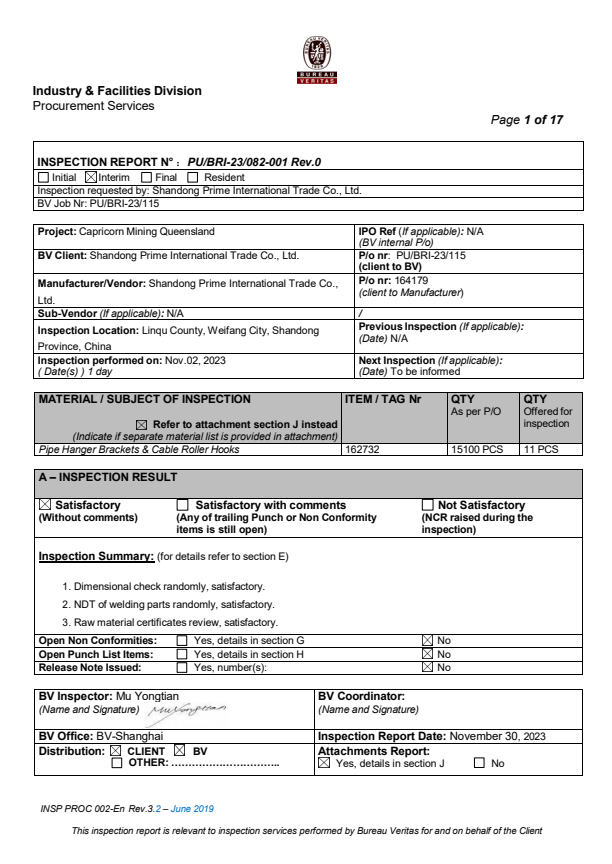

Quality Systems & Certifications

Our commitment to excellence is validated through rigorous international certifications, proprietary patents, and comprehensive quality management systems.

ISO 9001:2015 Certification

International standard for quality management systems, ensuring consistent quality and customer satisfaction across all production processes.

- Process Standardization

- Continuous Improvement

- Customer Focus

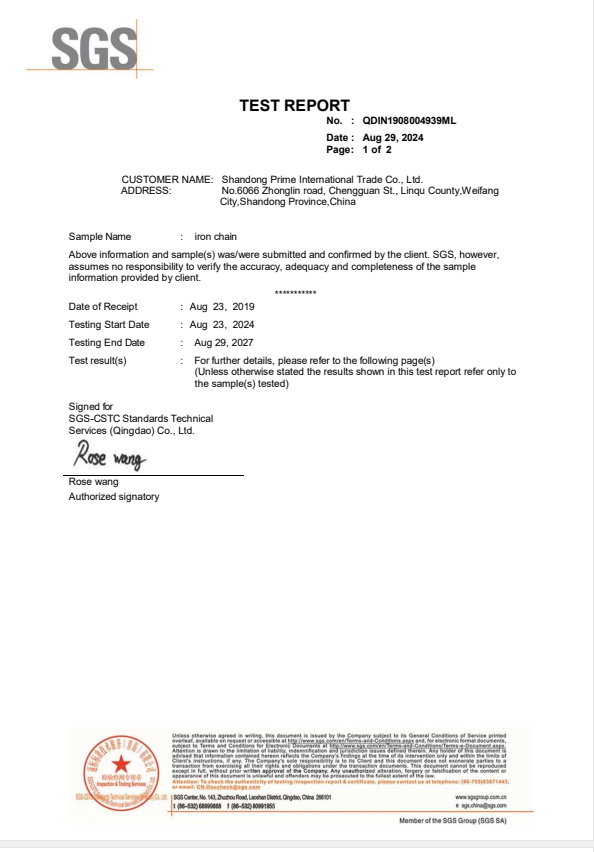

SGS Quality Verification

Global leader in inspection, verification, testing and certification services validating our quality standards and material integrity.

- Material Testing

- Quality Inspection

- Global Recognition

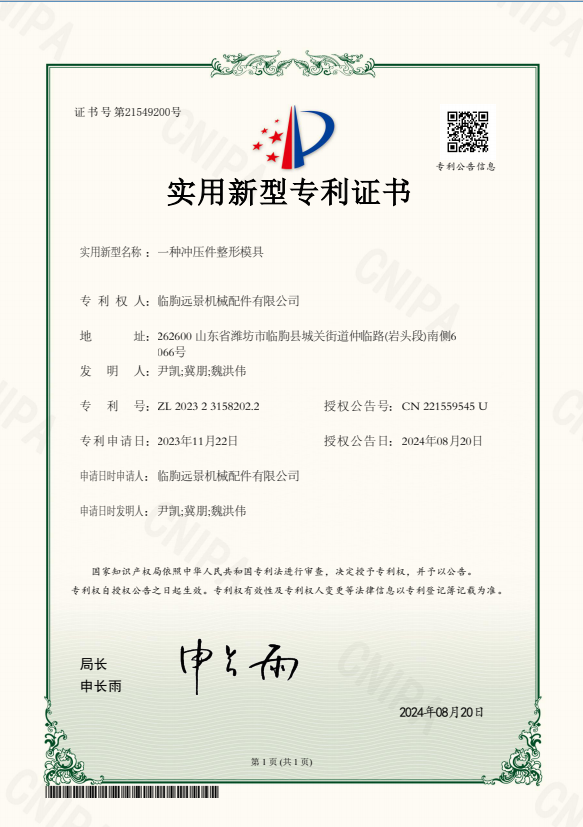

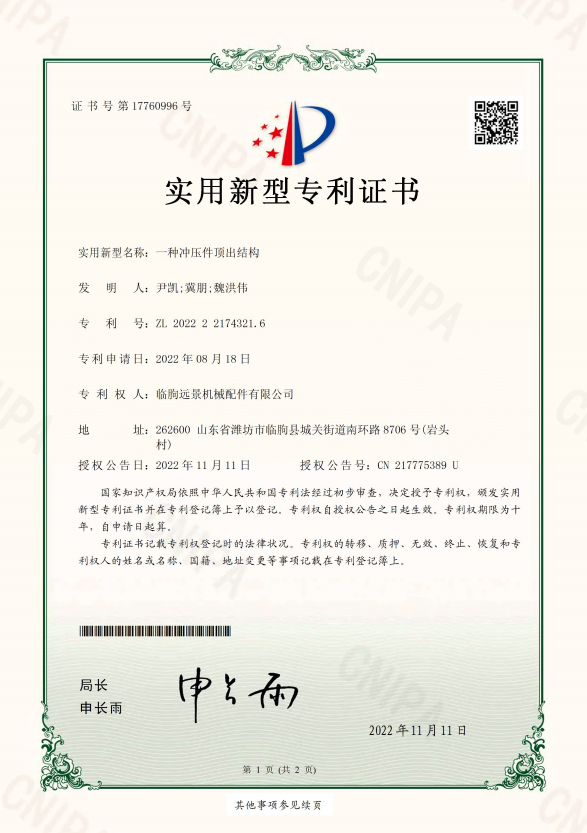

Proprietary Patents

Innovative casting technologies and processes protected by multiple patents, ensuring superior quality and production efficiency.

- Advanced Casting Methods

- Process Optimization

- Quality Enhancement

Request Your Custom Quote

Get a detailed quote for your custom metal casting requirements. Our experts will respond within 24 hours with technical specifications and pricing.

Your Privacy Matters

At Shandong Prime International Trade Co., Ltd., we are committed to protecting your confidential information with the highest standards of security and discretion.

Confidential Processing

All technical drawings, specifications, and project details are handled with strict confidentiality and stored securely.

No Third-Party Sharing

Your information is never shared with competitors or third parties without your explicit consent.

Secure Data Handling

ISO-compliant data security protocols ensure your sensitive information remains protected throughout our collaboration.

Professional Discretion

Our team maintains the highest level of professional discretion in all business communications and transactions.

30+ years of trusted partnerships with global enterprises. Your confidential projects are safe with us.